Water-based and oil-based coolant are the 2 major categories of surface grinding coolant. In the realm of machining and metalworking, the choice of coolant plays a pivotal role in determining the efficiency, quality, and sustainability of grinding processes. Among the available option, water-based and oil-based grinding coolants stand out as prominent contenders. Let’s delve into a comparative analysis of these two coolant types to discern their respective advantages and drawbacks.

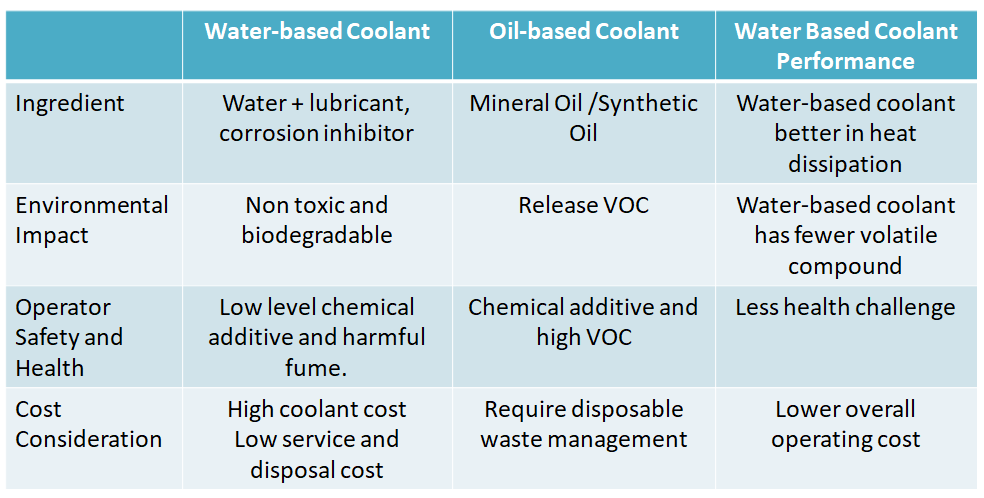

Let us compare both type of coolant with 4 perspective, namely

- Cooling and lubricant properties

- Environmental Impact

- Operator Safety and Health

- Cost Consideration

Cooling and Lubrication Properties:

Water-Based Coolants:

Water-based grinding coolants, primarily composed of water with additives for lubrication and corrosion inhibition, excel in heat dissipation. They efficiently absorb and dissipate heat generated during grinding operations, preventing thermal damage to work-pieces and cutting tools.

Additionally, water-based coolants offer excellent lubricating properties, facilitating smoother grinding action and reducing friction between the work-piece and abrasive wheel.

Oil-Based Coolants:

Oil-based grinding coolants, formulated from mineral oils or synthetic oil blends, also provide effective cooling and lubrication. However, their lubricating properties may not be as efficient as water-based counterparts. While oil-based coolants offer adequate heat dissipation, they may exhibit higher viscosity, leading to increased drag and heat buildup in the grinding zone.

Environmental Impact:

Water-Based Coolants:

One of the primary advantages of water-based grinding coolants lies in their minimal environmental impact. Comprising primarily of water, these coolants are non-toxic and biodegradable, posing minimal risk to the environment. Moreover, water-based coolants emit fewer volatile organic compounds (VOCs) compared to oil-based alternatives, contributing to cleaner air quality and reduced environmental pollution.

Oil-Based Coolants:

Oil-based grinding coolants, while effective in machining applications, pose environmental challenges due to their reliance on petroleum-derived oils. These coolants release VOCs and other harmful emissions into the atmosphere, contributing to air pollution and environmental degradation. Additionally, disposal of used oil-based coolants requires careful handling and proper waste management practices to prevent soil and water contamination.

Operator Safety and Health:

Water-Based Coolants:

Water-based grinding coolants offer a safer working environment for operators compared to oil-based alternatives. With lower levels of chemical additives and reduced exposure to harmful fumes, water-based coolants mitigate health risks associated with prolonged exposure to cutting fluids. This promotes worker well-being and complies with stringent occupational health and safety regulations.

Oil-Based Coolants:

Oil-based grinding coolants may pose health hazards to operators due to the presence of chemical additives and VOC emissions. Prolonged exposure to oil-based coolants can cause skin irritation, respiratory issues, and other health complications. Therefore, proper ventilation and personal protective equipment (PPE) are essential when using oil-based coolants to minimize health risks.

Cost Considerations:

Water-Based Coolants:

Water-based grinding coolants typically exhibit lower operating costs compared to oil-based alternatives. While the initial purchase price of water-based coolants may be slightly higher, their longer service life and lower disposal costs result in overall cost savings. Additionally, water-based coolants require less frequent replenishment and maintenance, reducing downtime and operational expenses.

Oil-Based Coolants:

Oil-based grinding coolants may have lower upfront costs, but their ongoing maintenance and disposal expenses can be considerable. The need for frequent replenishment, filtration, and waste disposal adds to the operational costs associated with oil-based coolants. Moreover, the environmental regulations governing the disposal of used oil-based coolants may entail additional compliance costs for manufacturers.

In summary, the choice between water-based and oil-based grinding coolants hinges on various factors, including cooling and lubrication properties, environmental impact, operator safety, and cost considerations. While both coolant types offer distinct advantages, water-based coolants emerge as a more sustainable and operator-friendly solution, with lower environmental impact and operating costs. By carefully weighing these factors and aligning them with specific machining requirements, manufacturers can make informed decisions to optimize grinding processes and achieve superior outcomes.